Welcome to

Powerlink Oil Refinery Ltd

Transformer oil when you need results

Unmatched Quality of Electrical Insulating oil.

Transformer oil or insulating oil is usually a highly refined mineral oil that is stable at high temperature and has excellent electrical insulating properties. It is used in oil-filled power transformers, some types of high voltage capacitors, high voltage switches and circuit breakers. Its function is to insulate, suppress corona and arcing, and to serve as a coolant. The oil helps cool the transformer. Because it also provides part of the electrical insulation between internal live parts, transformer oil must remain stable at high temperature for an extended period. To improve cooling of large power transformers, the oil filled tank may have external radiators through which the oil circulates by natural convection. Sub standard & inferior quality of oil can harm the equipment in many ways and ensure to use only genuine and standard oil procured from reliable source only. The easiest way to explain the reasoning for proper transformer oil maintenance is to compare a Transformer to a car. A car requires oil for lubrication while a Transformer requires oil for insulation and cooling. Just as a car requires regular checks of both oil quality and oil level, a transformer requires the same proactive treatment. Oil in each instance degrades over time resulting in the potential for failure or costly repair bills. Oil should be procured from reliable source or use of “TRANSPOWER” Transformer oil will add years to the life of your Equipment’s/Transformer. We known as best transformer oil manufacturer and supplier in India

Applications of Transformer Oil

Oil Filled Transformers

Circuit Breakers

Tap Changers

Switches

Fuses

Oil-immersed electrical equipment

Welding set

X-ray Machine

Transparent Armor and Military Glass Testing

Submersible Pump

Outstanding Features

High dielectric strength

High Flash Point

Better heat transfer properties than other traditional oil

Non corrosive to copper and copper alloys

Excellent Insulating Characteristics

Resists oxidation and deposit formation

Free from PCBs Compatible with material used in Transformers & equipments

Low Power factor inhibited to minimize the formation of acids and sludge from Oxidation

Good low temperature fluidity due to very low pour point

Specification

Oil Filled Transformers

Circuit Breakers

Tap Changers

Switches

Fuses

Oil-immersed electrical equipment

Welding set

X-ray Machine

Transparent Armor and Military Glass Testing

Submersible Pump

Knowledge Base

Transformer oil or insulating oil is usually a highly refined mineral oil that is stable at high temperatures and has excellent electrical insulating properties. It is used in oil-filled transformers, some types of high voltage capacitors, fluorescent lamp ballasts, and some types of high voltage switches and circuit breakers. Its functions are to insulate, suppress corona and arcing, and to serve as a coolant.

A mineral oil is any of various colourless, odourless, light mixtures of ALKANES in the C15 to C40 range from a non-vegetable (mineral) source, particularly a distillate of petroleum. The name mineral oil by itself is imprecise, having been used to label many specific oils over the past few centuries. Other names, similarly imprecise, include white oil, liquid paraffin, and liquid petroleum. Most often, mineral oil is a liquid by-product of the distillation of petroleum to produce gasoline and other petroleum-based products from crude oil. A mineral oil in this sense is transparent, colourless oil composed mainly of alkenes and cyclic paraffin’s, related to petroleum jelly (also known as “white petrolatum”).

Transformer oils are subject to electrical and mechanical stresses while a transformer is in operation. In addition there is contamination caused by chemical interactions with windings and other solid insulation, catalyzed by high operating temperature. The original chemical properties of transformer oil change gradually, rendering it ineffective for its intended purpose after many years. Oil in large transformers and electrical apparatus is periodically tested for its electrical and chemical properties, to make sure it is suitable for further use. Sometimes oil condition can be improved by filtration and treatment

The oil helps cool the transformer. Because it also provides part of the electrical insulation between internal live parts, transformer oil must remain stable at high temperatures for an extended period. To improve cooling of large power transformers, the oil-filled tank may have external radiators through which the oil circulates by natural convection. Very large or high-power transformers (with capacities of thousands of kVA) may also have cooling fans, oil pumps, and even oil-to-water heat exchangers.

Large, high voltage transformers undergo prolonged drying processes, using electrical self-heating, the application of a vacuum, or both to ensure that the transformer is completely free of water vapour before the cooling oil is introduced. This helps prevent corona formation and subsequent electrical breakdown under load.Oil filled transformers with a conservator may have a gas detector relay (Buchholz relay). These safety devices detect the build up of gas inside the transformer due to corona discharge, overheating, or an internal electric arc. On a slow accumulation of gas, or rapid pressure rise, these devices can trip a protective circuit breaker to remove power from the transformer. Transformers without conservators are usually equipped with sudden pressure relays, which perform a similar function as the Buchholz relay.

To ensure satisfactory service, the utmost care in handling oil is essential. Filled drum of Transformer oil should be kept under cover. In practice owing to contamination in the containers, difficulty may be experienced in maintaining the purity of the oil when it is transferred from one vessel to another, and once a vessel or drum has been filled with moist oil it is extremely difficult to clean. Drum should be clearly marked to indicate whether they are for clean or for dirty oil and should be reserved for the type indicated.

Transformer oil store in the storage tank should be preferably with cover and air tight fitted with lid and small pipe with silica get fitted on top for breathing the tank. The end of the delivery pipe should be held below the surface of the oil in order to avoid splashing. The storage tank should be filled from the bottom.

PRECAUTIONS: Every precaution shall be taken , when sampling so as not to contaminate the Transformer oil with dirt, dust fibrous matter or moisture. Outdoor sampling of Transformer oil in rain, fog or high wind should be avoided. The operator is warned not to permit his hands to come in contact the sample or the internal surface of sampling container. The sample of Transformer oil should be protected against all kinds of light radiation during sampling & storage. The sample bottle shall not be opened immediately. It is necessary to wait till the temperature of the sample is in equilibrium with room temperature.

Sampling equipment: All sampling equipments should be reserved for exclusively taking the sample. The equipment shall be perfectly clean and dry and preferably be made of glass or stainless steel.

Sampling from Road Tanker may be done through the Tank outlet. The sample should be drawn after the vehicle has been allowed to stand for at least one hour from the time of its arrival. Sampling from Drum should be taken only after the drums have been allowed to stand for at least 8 hours with the bung intact on top, protected from dust or rain. The bungare and top surface of the drum shall be cleaned with lint free dry cloth before opening.

Follow all procedure as per IS 6855:2003 Method of Sampling for Liquid Dielectrics issue by Bureau of Indian Standard

DIELECTRIC STRENGTH OF TRANSFORMER OIL

Dielectric Strength of Transformer Oil is also known as Breakdown Voltage of transformer oil or BDV of transformer oil. Break down voltage is measured by observing at what voltage, sparking strants between two electrods immerged in the oil, separated by specific gap. low value of BDV indicates presence of moisture content and conducting substances in the oil. For measuring BDV of transformer oil, portable BDV measuring kit is generally available at site.In this kit, oil is kept in a pot in which one pair of electrodes are fixed with a gap of 2.5 mm (in some kit it 4mm) between them. Now slowly rising voltage is applied between the electrodes. Rate of rise of voltage is generally controlled at 2KV/s and observe the voltage at which sparking starts between the electrodes. That means at which voltage Dielectric Strength of transformer oil between the electrodes has been broken down. Generally this measurement is taken 3 to 6 times in same sample of oil and the average value of these reading is taken. BDV is important and popular test of transformer oil, as it is primary indication of health of oil and it can be easily carried out at site.

Dry and clean oil gives BDV results, better than the oil with moisture content and other conducting impurities. Minimum Breakdown Voltage of transformer oil or Dielectric Strength of transformer oil at which this oil can safely be used in transformer, is considered as 30 KV.

SPECIFIC RESISTANCE ( RESISTIVITY ) OF TRANSFORMER OIL

This is another important property of transformer oil. This is measure of DC resistance between two opposite sides of one cm3is taken as ohm-cm at specific temperature. With increase in temperature the resistivity of oil decreases rapidly. Just after charging a transformer after long shut down, the temperature of the oil will be at ambient temperature and during full load the temperature will be very high and may go up to 90oC at over load condition. So resistivity of the insulating oil must be high at room temperature and also it should have good value at high temperature as well. That is why specific resistance or resistivity of transformer oil should be measured at 27oC as well as 90oC.

Minimum standard Specific Resistance of Transformer oil at 90oC is 35X 1012 ohm – cm and at 27oC it is 1500X1012 ohm – cm

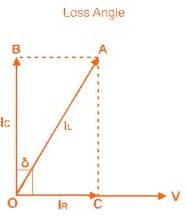

Dielectric Dissipation Factor is also known as loss factor or tan delta of transformer oil. When a insulating materials is placed between live part and grounded part of an electrical equipment, leakage current will flow. As insulating material is dielectric in nature the electric current through the insulation ideally leads the voltage by 90o ground of the equipment. But in reality no insulating materials are perfect dielectric in nature. Hence electric current through the insulator will lead the voltage with an angle little bit shorter than 90o of the angle by which it is short of 90o transformer oil. More clearly, the leakage current through an insulation does have two component one is capacitive or reactive and other one is resistive or active. Again it is clear from diagram. Here voltage means the instantaneous voltage between live part and is called Dielectric Dissipation Factor or simply tan delta of Value of ′δ′ Which is also known as oil loss angle, is smaller, means resistive component of the current IR is smaller which indicates high resistive property of the insulating material.

High resistive insulation is good insulator. Hence it is desirable to have loss angle as small as possible. So we should try to keep the value of tanδ as small as possible. High value of this tanδ is an indication of presence of contaminants in transformer oil. Hence there is a clear relationship between tan δ and resistivity of insulating oil.

Resistivity of the insulating oil is decreased, the value of tan-delta increases and vice verse. So both resistivity test and tan delta test of transformer oil are not normally required for same piece of insulator or insulating oil. In one sentence it can be said that, tanδ is measure of imperfection of dielectric nature of insulation materials like oil.

Generally there are two types of Transformer Oil used in transformer

Naphthenic oil is more easily oxidized than Paraffin oil. But oxidation product i.e. sludge in the naphtha oil is more soluble than Paraffin oil. Thus sludge of naphthenic based oil is not precipitated in bottom of the equipment’s transformer. Hence it does not obstruct convection circulation of the oil, means it does not disturb the transformer cooling system. But in the case of Paraffin oil although oxidation rate is lower than that of Naphthenic oil but the oxidation product or sludge is insoluble and precipitated at bottom of the tank and obstruct the transformer cooling system. Although Paraffin based oil has above mentioned disadvantage but still in our country it is generally used because of its easy availability. Another problem with paraffin based oil is its high pour point due to the wax content, but this does not effect its use due to warm climate condition of India.

Transformer Oil forms a very significant part of the transformer insulation system and has the important functions of acting as an electrical insulation as well as coolant to dissipate heat losses. Transformer Oil will be obtained by fractional distillation and subsequent treatment of crude oil. Transformer Oil consists of organic compounds namely paraffins, naphthene’s, aromatics and olefins. All these compounds are hydrocarbons, so Transformer Oil is is a pure hydrocarbon mineral oil.

Different physical properties of Transformer Oil are

The amount of free and dissolved water present in the oil is its moisture content and is expressed in ppm (parts per million by weight, mg/kg). Presence of oil is harmful since it adversely affects the electrical characteristics of the oil and accelerates the deterioration of the insulating paper. For good Transformer Oil Moisture Content Should be low.

It is the temperature at which oil gives so much vapour that this vapour which mixes with the air forms an ignitable mixture and gives momentary flash on application of the flame under prescribed conditions. A minimum flash point is specified in order to prevent the risk of fire that might be result of accidental ignition. For good Transformer Oil Flash Point should be higher (140 Centigrade).

Most Important: Some spurious oil is being supplied by some spurious Trader in the Name of Transformer oil which looks like Transformer oil but actually this type of oil having flash point of about 100 deg C is very dangerous to public life and property. Oil will be oxidized very soon and caught fire when the temperature reaches near 100 deg .C

Interfacial Tension is the measure of molecular attractive force between the oil and water molecules at their interfacial level. By testing for Interfacial tension we can determine the soluble polar contaminants present in the oil which reduces the molecular attraction force between the oil and water.

It measures the oil resistance to the continuous flow without the effect of the external forces. The oil must be mobile to transfer the heat in a better manner from the core to the transformer radiators where heat is dissipated. So Viscosity of the transformer oil should be very less. With the decrease in the temperature of the oil viscosity increases, so it is necessary for transformer oil to have low viscosity at low temperatures.

The temperature at which transformer oil will just flow under the prescribed conditions is known as the pour point. Pour Point should be low for good transformer oil, i.e, transformer oil say at -6deg cent starts just flowing, so pour point should be low so that oil can start flow even at low temperatures.

Different Chemical Properties Of Transformer Oil are

It is the measure to determine the free organic and inorganic acids present in the oil expressed in terms of milligrams of KOH required neutralizing the total free acids in one gram of oil. Oxidation in the transformer oil is due to reaction between the hydrocarbons present in the oil and air. Copper present in the copper acts as catalyst to this reaction. The products of oxidation are injurious to the insulation system of the transformer and corrode the transformer components. So measurement of the total acidity is the tool to determine the capability of oil for non formation of acids during the life. For good transformer oil Total acidity should be low.

Oxidation Stability is the measure of neutralization value and sludge after oil is aged by simulating the actual service conditions of the oil.

Crude petroleum contains sulphur compounds. Most of this s removed at the time of refining process. Presence of corrosive sulphur results in pitting and black deposit on the surface of the bare copper used in copper which hinders the heat dissipation ability.

Request a Call back

Do you have questions about Powerlink Oil Refinery Products or Quality? Send us an email and we’ll get in touch shortly, you may contact over on call between 8:00 a.m. to 8:00 p.m. Monday to Saturday – we would be delighted to speak with you.

Your details are kept strictly confidential as per our Privacy Policy.

We are the foremost manufacturer and exporter of stable and consistent quality of Industrial Automotive Lubricants and Oils.

BE IN TOUCH

PHONE: +9811274820

EMAIL: [email protected]

ADDRESS:

Powerlink Oil Refinery Ltd

18 Modern Industrial Estate, Bahadurgarh Haryana 124507

Transformer oil or insulating oil is usually a highly refined mineral oil that is stable at high temperature and has excellent electrical insulating properties. It is used in oil-filled power transformers, some types of high voltage capacitors, high voltage switches and circuit breakers. Its function is to insulate, suppress corona and arcing, and to serve as a coolant. The oil helps cool the transformer. Because it also provides part of the electrical insulation between internal live parts, transformer oil must remain stable at high temperature for an extended period. To improve cooling of large power transformers, the oil filled tank may have external radiators through which the oil circulates by natural convection. Sub standard & inferior quality of oil can harm the equipment in many ways and ensure to use only genuine and standard oil procured from reliable source only. The easiest way to explain the reasoning for proper transformer oil maintenance is to compare a Transformer to a car. A car requires oil for lubrication while a Transformer requires oil for insulation and cooling. Just as a car requires regular checks of both oil quality and oil level, a transformer requires the same proactive treatment. Oil in each instance degrades over time resulting in the potential for failure or costly repair bills. Oil should be procured from reliable source or use of “TRANSPOWER” Transformer oil will add years to the life of your Equipment’s/Transformer. We known as best transformer oil manufacturer and supplier in India